|

|

|

|

QUY400 Crawler Crane Main features 1. This crawler crane is equipped with a VOLVO electronic fuel injection engine which has such advantages as strong power, low noise, slight vibration and excellent environmental protection performance. 2. The slewing ring imported from Germany has high reliability and long service life. 3. The PLC controller imported from Finland , which is manufactured specially for military industrial products, has strong shock resistance and anti-interference ability and can adapt to various adverse working conditions. 4. The automatic exhaust device fitted in hydraulic system can discharge the air in the system in time so as to efficiently prevent the hook from getting out of control. 5. The hydraulic system is fitted with several detection points, from which the signals detected will be transmitted to PLC controller. After analyzing the signal, the PLC controller, which has applied the limit load control technology, can make the engine keep in optimal working condition. 6. The contactless and Bus-controlled electrical control lever, which has a wide adjusting range, can ensure excellent jogging performance. The control lever is fitted with a function key, which can avoid inadvertent operation because the operation of the control lever will be of no use without the function key pressed. Such control lever is practical and has a long service life. 7. When PLC control system or touch screen fails, emergency measures can be taken to ensure that the system functions normally. 8. This crawler crane is equipped with a heating & cooling air conditioning system, which has two sets of heating control system. When the air conditioning is used in cold weather, the two sets of heating control system can be used to guarantee optimal heating effect. 9. The crawler crane can carry out self-assembly/dismantling motion without the help of other auxiliary crane; the connecting parts are driven by the power pin cylinder; and the auxiliary mechanism of boom frame is designed distinctively. All the three features make the assembly, dismantling, conversion of the machine on the site and transportation between sites quicker and more convenient. 10. The distinctive method of mounting the ballast is of simplicity, reliability, so the ballast can be fitted and removed easily. |

|

QUY400 Crawler Crane Main Technical Specifications |

Item |

Value |

Remarks |

|||

Max. lifting capacity /Radius |

Without superlift counterweight |

t ¡Á m |

400 ¡Á 6 |

|

|

With superlift counterweight |

t ¡Á m |

400 ¡Á 8 |

|

||

Main boom length |

m |

24~84 |

|

||

Length of main boom with light boom head |

Without superlift counterweight |

m |

48~102 |

|

|

With superlift counterweight |

m |

78~126 |

|

||

Deadweight with basic boom |

t |

350 |

|

||

Fixed jib length |

m |

12~36 |

|

||

Max. lifting capacity of fixed jib |

t |

80 |

|

||

Offset angle of Fixed jib ¡ã |

¡ã |

10,30 |

|

||

Max. length of main boom with fixed jib |

Without superlift counterweight |

m |

72 £« 36 |

|

|

With superlift counterweight |

m |

84 £« 36 |

|

||

Luffing jib length |

Without superlift counterweight |

m |

24~66 |

|

|

With superlift counterweight |

m |

24~84 |

|

||

Max. lifting capacity of luffing jib |

Without superlift counterweight |

m |

140 |

|

|

With superlift counterweight |

m |

180 |

|

||

Main boom angle under luffing jib working condition |

¡ã |

65,75,85 |

|

||

Max. length of main boom with luffing jib |

Without superlift counterweight |

m |

54 £« 66 |

|

|

With superlift counterweight |

m |

84 £« 84 |

|

||

Max. speed of single rope on drum |

Main winch |

m/min |

0~140 |

|

|

Auxiliary winch |

m/min |

0~140 |

|

||

Derricking winch |

m/min |

2 ¡Á 0~60 |

|

||

Luffing winch |

m/min |

0~125 |

|

||

Superlift derricking winch |

m/min |

0~146 |

|

||

Hoisting winch for tip boom |

m/min |

0~110 |

|

||

Slewing speed |

rpm |

0~1.0 |

|

||

Traveling speed |

km/h |

0~1.4 |

|

||

Gradeability |

£¥ |

20 £¥ |

|

||

Ground pressure |

MPa |

0.149 |

|

||

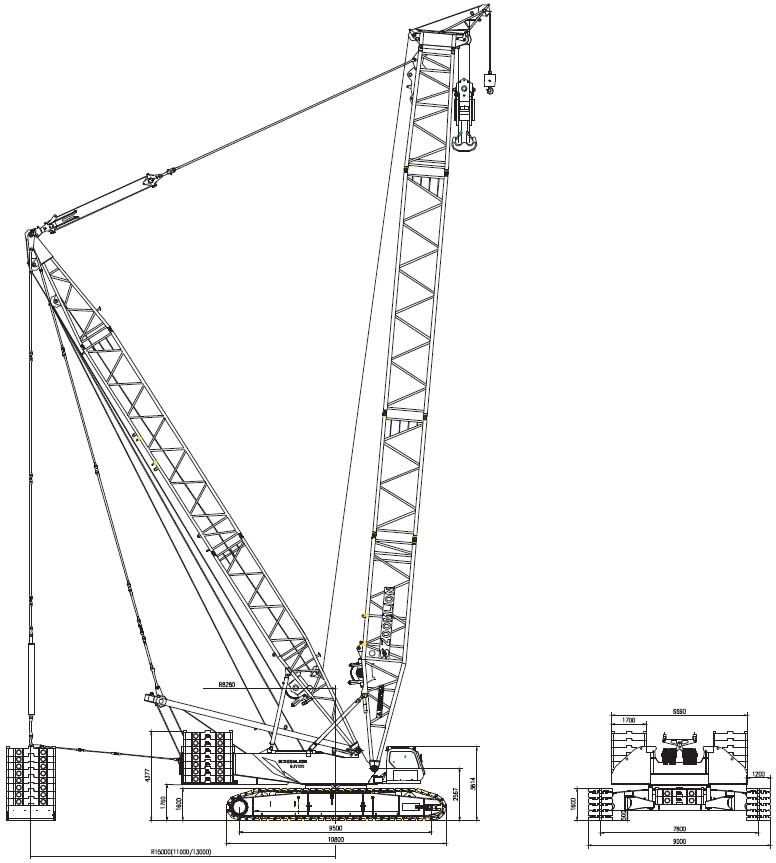

Overall dimensions (L¡ÁW¡ÁH) of basic machine in transportation condition |

mm |

13900 ¡Á 3100 ¡Á 3240 |

With mast |

||

Engine |

Rated power/ rotational speed kW/rpm |

343/1800 |

|

||

Torque/ rotational speed Nm/rpm |

2150/1100 ¡« 1500 |

|

|||

Emission standard |

EU Stage II |

|

|||

Crawler gauge ¡Áground contact length ¡Átrack shoe width mm |

7800 ¡Á 9500 ¡Á 1200 |

|

|||

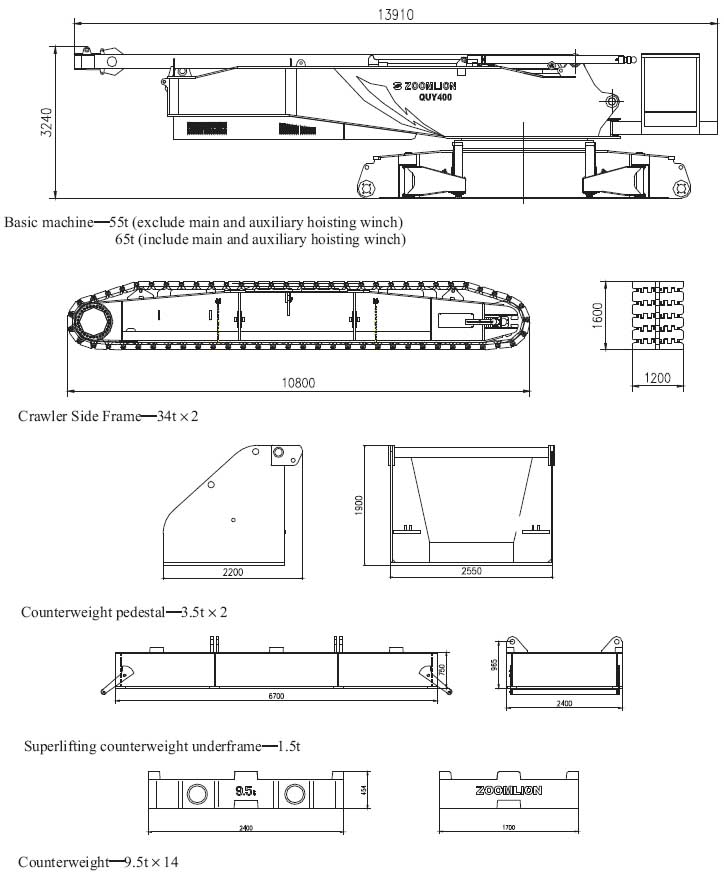

Outline Dimensions and Weight of Main Transport Components

|

|

|

Technical instruction |

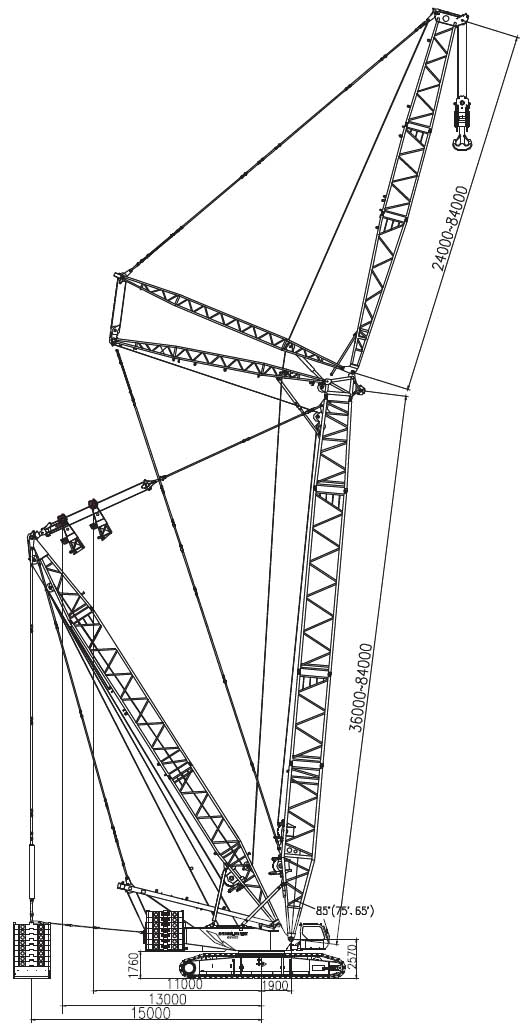

1.Operating Conditions and Boom System |

|

There are two kinds of operating conditions: standard

operating condition and superlifting operating condition. The

boom is lattice structure and mainly made of imported highstrength

tubular product. Pendant plate is made of imported

high-strength plate material. Standard operating conditions Main boom operating condition Main boom length:24m~84m Light-duty boom length:48m~102m Adjusting lengthened boom section length for main boom: 6m or 12m Fixed fly jib operating condition Main boom length:30m~72m Fixed fly jib length:12m~36m Adjusting lengthened boom section length for fixed fly jib: 12m Luffing fly jib operating condition Main boom length:30m~54m Luffing fly jib length:24m~66m Adjusting lengthened boom section length for luffing fly jib: 6m or 12m Superlifting operating conditions Superlifting main boom operating condition Main boom length:36m~84m Light-duty boom length:78m~126m Superlifting fixed fly jib operating condition Main boom length:36m~84m Fixed fly jib length:12m~36m Superlifting luffing fly jib operating condition Main boom length:36m~84m |

2.Mechanisms |

Main and Auxiliary Hoist Mechanisms |

| The hoist mechanism consists of imported axial piston

variable displacement hydraulic motor, balanced valve,

reducer, normally closed brake and wire rope. It is

independent of other mechanisms to be operated. Wire rope is a kind of special torsion-resistant one imported from Germany. The maximum single rope speed of main and auxiliary winch is 140m/min. The synchronizing controller will work when main and auxiliary hoist mechanisms work synchronously. Hosting winch of runner is optional. The maximum single rope speed is 110m/min. |

Boom Hoist Mechanism |

| Luffing gear and superlifting luffing mechanism consist of

imported concealed axial piston variable displacement

hydraulic motor, balanced valve, reducer, normally closed

brake and wire rope. Main luffing mechanism consists of

imported axial piston constant displacement hydraulic motor,

balanced valve, reducer, normally closed brake and wire rope. Wire rope is a kind of special torsion-resistant one imported from Germany. Max. single rope speed on main luffing gear is 2¡Á60m/min. Max. single rope speed on luffing gear of luffing fly jib is 125m/min. Max. single rope speed on luffing gear of superlifting luffing fly jib is 146m/min. |

Slewing Mechanism |

| Adopting closed bi-drive double-slewing mechanism, slewing

mechanism consists of constant displacement hydraulic motor,

gear reducer, brake, pinion gear and slewing ring etc. With controllable sliding control, slewing gear can reduce impact to ensure slewing start/ brake more stably. With imported original external gear and roller type slewing ring (triple row) from Germany, slewing gear possesses the advantages of great load capacity and high accuracy to ensure the stability and accuracy of slewing. Slewing can realize stepless speed regulation varying from 0 to 1.0r/min. |

Traveling Mechanism |

| It adopts four-motor and double-reducer. Hydraulic motor,

traveling reducer and balanced valve are all imported from

Germany. Two sets of joysticks respectively control two

tracks' traveling to realize straight-line traveling, one-sided

steering, differential steering, spot turn and traveling with load

etc., which ensure the crawler crane has great mobility and

flexibility. Traveling speed: 0~1.4km/h Gradeability: 30%. Tension degree of track can be adjusted by individual pumping station. It is very quick, convenient and reliable. |

Mast Raising Mechanism |

| It consists of mast, mast raising cylinder and auxiliary hydraulic system etc. It is used for self-assembly/dismantling of the complete vehicle (or the change of working place). Before doing this work, the mast should be raised 90¡ã over the horizontal level so as to connect pendant plate, assemble boom and install crawler side frame and counterweight. |

Operator's Cab Rotary and Pitching Mechanism |

| Through operateing the oscillating cylinder, operator's cab

can rotate 90¡ã from the side of slewing table to the front of

slewing table and then be fixed by positioning pin, which can

reduce the width of complete vehicle to make it convenient for

transporting. Operator's cab is tilted by cylinder. When the lifting height is high, operator's cab can be raised upwards for 20¡ã to broaden the driver's vision greatly. |

Outrigger Raising Mechanism and Track Self- assembly/dismantling Mechanism |

| Outrigger raising mechanism and track selfassembly/dismantling mechanism consist of outriggers,

outrigger cylinder, outrigger valve and track power pin

etc. Outrigger raising mechanism is the main load bearing

mechanism when self-assemble/dismantle track. Through

mast and mast raising mechanism, track selfassembly/dismantling mechanism is used for lifting

crawler side frame which is connected with frame by power pin. Outrigger raising mechanism and track selfassembly/dismantling mechanism can assemble/dismantle crawler side frame without auxiliary lifting equipment, which can improve working efficiency and reduce labor intensity and avoid danger of manual operation. |

Outrigger raising mechanism and track self- assembly/dismantling mechanism |

| Outrigger raising mechanism and track selfassembly/dismantling mechanism consist of outriggers,outrigger cylinders, outrigger valves and track power pin etc. Outrigger raising mechanism is the main load bearing mechanism when self-assemble/dismantle track. Through mast and mast raising mechanism, track self-assembly/dismantling mechanism is used to lift crawler side frame which is connected with frame by power pin. Outrigger raising mechanism and track self-assembly/dismantling mechanism can assemble/dismantle crawler side frame without auxiliary lifting equipment, which improves working efficiency and reduces labor intensity and avoids danger of manual operation. |

3.Systems |

Hydraulic System |

| Hydraulic system consists of main pump, control valve,hydraulic motor, hydraulic oil tank and cooler etc. Hydraulic

system adopts advanced pump control system in the world and

its main components such as pump, motor and main loop

valves are all imported from Germany and have advantages of

high efficiency, energy-saving, high reliability and long service

life. Main hydraulic pump: is piston variable displacement pump with tandem gear pump, driven by engine. Oil source of auxiliary mechanism: variable displacement constant pressure pump. Main control valve: pilot electro-hydraulic control valve Control method for main loop: controlled by pump control system and joysticks. Control of auxiliary mechanism: electromagnetic reversing valve blocks. It is equipped with unloading overflow valve. Outrigger operating: electromagnetic multiunit valve controlled by electrical control-box. Hydraulic oil tank capacity: 1000L. Oil filter: oil filter of oil return circuit, precision filter of oil control circuit. Cooler: aluminium radiator, with electric fan driven by hydraulic motor. |

Electrical System |

| This system with 24V DC and earth negative, has two 195 AH

accumulators. Electric appliance of complete vehicle mainly includes power, engine start, engine shut-down, indicator light, annunciator, illumination, fan, wiper, horn, hoisting limiter, hydraulic oil cooling fan, digitized display, PLC controller, load moment limiter, preheating device for engine and safety equipment etc, which ensure safe operation and excellent working environment of the crane. The complete vehicle adopts CANbus technology, which connects the engine, PLC controller, load moment limiter and digitized display efficiently, and possesses trouble detecting and self-diagnosis function. The crane is also equipped with GPS/GPRS global positioning system and remote trouble diagnosis system. |

Power system |

| Engine: imported original VOLVO electric spraying diesel

engine with CAN-bus interface. Rated output power: 343kw, 1800r/min Max. output torque: 2150Nm, 1100~1500r/min Emission standard: U.S. EPA Tier II and EU StageII Fuel tank capacity is 700L which ensures long working hours of engine. |

Centralized Display System |

| Large LCD intercalates Multilanguage display and can centralized display operating condition signals collected by PLC controller, such as engine rotary speed, water temperature, fuel pressure, hydraulic pump pressure, main motor pressure, operating level of basic machine and wind speed at the top of boom etc. It can monitor working state in real time and give out a yellow or red warning signal when the working state of crane is abnormal. |

Centralized Lubrication System |

| It adopts three sets of centralized lubrication system (one is for

superstructure and the other two are for chassis), which is convenient for maintenance and can reduce the abrasion of components. |

CCTV |

| It can monitor the winding state of wire rope on winch mechanisms such as hoisting winch, main luffing gear, luffing gear of luffing fly jib, luffing gear of superlifting luffing fly jib etc. It is also used for monitoring the operating condition of superlifting counterweight and the circumstances in the working area. |

4.Safety equipment |

| The crane adopts mechanical, electric and hydraulic safety equipments and warning devices so as to ensure the crane can work safely. |

Load Moment Limiter |

| It consists of load moment display and digitized LCD. When

actual load moment reaches 90% of rated load moment, the

warning lamp lights up and the buzzer alarms; when it reaches

rated load moment, the crane stops working automatically to

prevent accidents occur due to overload during operation and

ensure normal and safe work. The digitized LCD displays the following data: Moment ratio Elevation angle of main boom Main boom length Working radius Actual load Permissible lifting load Max. permissible lifting height |

Overflow Valves of Hydraulic System |

| It can restrain the abnormal high pressure in loop to prevent hydraulic oil pump and hydraulic motor from being damaged and prevent hydraulic system from overloading. |

Over-wind and Over-release Protection Device for Wire Rope |

Hoisting Limiter |

Boom Angle Indicator |

Motion Limiter |

Level Sensor of the Complete Vehicle |

Anti-unhook Device |

Anemoscope |

Operator s Cab |

| It adopts all-steel structure. Its all sides are made of hardened glass, and the roof and the front window are furnished with laminated glass. It is equipped with sun visor, adjustable seat, wiper, electric control handles, load moment display, digitized display, auxiliary remote control box operation assembly of switches, air conditioner, electric fan, illumination lamp, radio (CD player, mp3 player and DVD player are optional), cigarette lighter, fire extinguisher etc. Wide vision and spacious room in the cab fully embody ergonomic design. |

Hook |

| It is equipped with rotatable hook and anti-unhook device. 400t hook (200t 2 hook is optional) with 16 sheaves 100t main hook with 4 sheaves 50t main hook with 2 sheaves 16t hook is cylindrical member. |

Optional Equipment |

| 250t cathead, 250t hook Hoisting winch of runner, wire rope and runner |

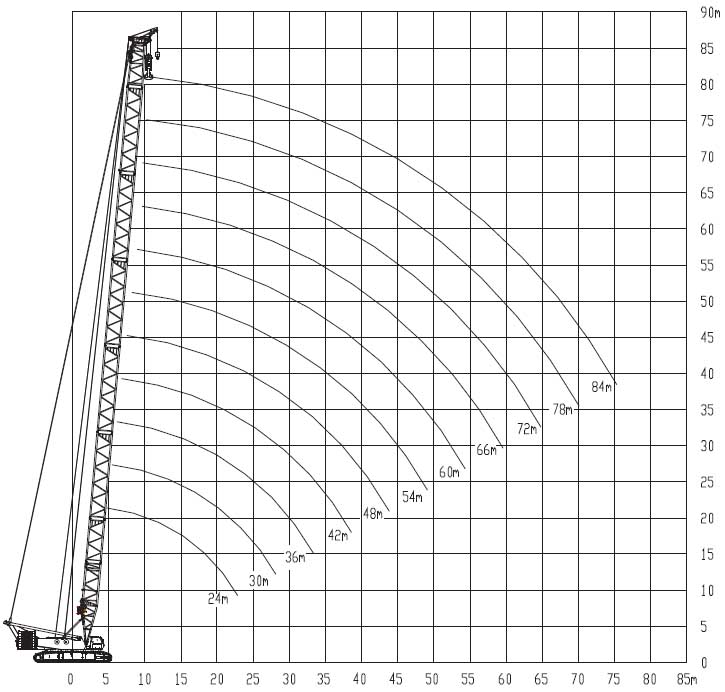

Lifting Performance

|

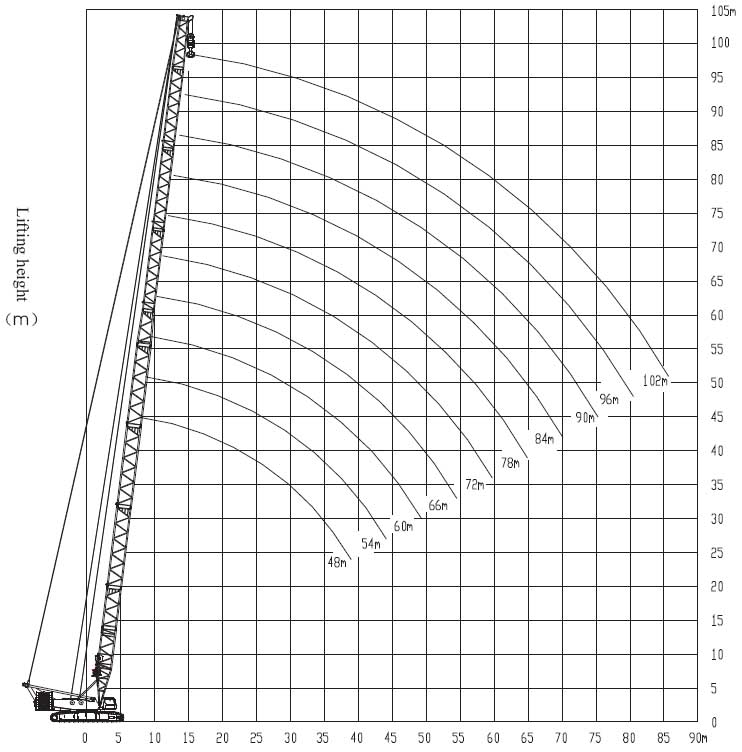

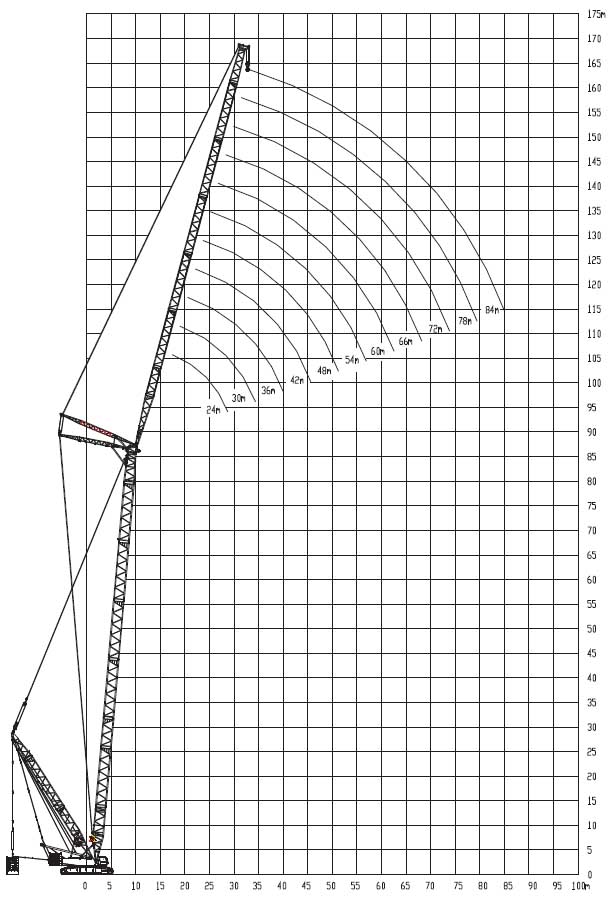

Heavy-duty main boom lifting height curve

|

|

Heavy-duty main boom load rating chart

(counterweight is 140+40t) |

| Boom length(m) |

24 |

30 |

36 |

42 |

48 |

54 |

60 |

66 |

72 |

78 |

84 |

Falls Radius(m) |

32 |

20 |

20 |

16 |

14 |

14 |

12 |

12 |

10 |

8 |

8 |

6 |

400 |

305 |

|

|

|

|

|

|

|

|

|

6.5 |

340 |

285 |

|

|

|

|

|

|

|

|

|

7 |

305 |

270 |

268 |

264 |

|

|

|

|

|

|

|

8 |

260 |

243 |

238 |

231 |

228 |

|

|

|

|

|

|

9 |

230 |

216 |

212 |

206 |

204 |

196 |

|

|

|

|

|

10 |

205 |

195 |

192 |

186 |

184 |

177 |

160 |

147 |

|

|

|

11 |

185 |

178 |

175 |

169 |

167 |

160 |

152 |

145 |

134 |

|

|

12 |

170 |

163 |

160 |

155 |

152 |

146 |

139 |

133 |

127 |

120 |

106 |

14 |

142 |

139 |

136 |

132 |

129 |

124 |

118 |

113 |

108 |

103 |

98 |

16 |

118 |

118 |

116 |

113 |

111 |

107 |

102 |

97.5 |

93.5 |

90 |

85 |

18 |

100 |

100 |

99 |

98 |

97 |

93.5 |

89.5 |

85.5 |

81.5 |

78 |

75 |

20 |

86 |

86 |

86 |

85 |

84 |

82 |

79 |

76 |

72.5 |

69 |

66 |

22 |

76 |

76 |

75 |

74 |

73 |

72.5 |

70 |

67.5 |

65 |

62 |

59 |

24 |

67 |

66 |

65 |

65 |

64.5 |

62.5 |

60.5 |

58 |

55 |

53 |

|

26 |

60 |

60 |

59 |

58 |

57.5 |

56 |

54.5 |

52.2 |

50 |

48 |

|

28 |

54 |

52.5 |

52 |

51.5 |

50 |

49 |

47.5 |

45 |

43 |

||

30 |

49 |

47 |

47 |

46.5 |

45 |

44 |

43 |

41 |

39 |

||

32 |

44.5 |

43 |

43 |

42 |

40.5 |

40 |

39 |

37 |

35.5 |

||

34 |

40 |

39 |

38.5 |

37 |

36 |

35.5 |

33.5 |

32 |

|||

36 |

36 |

36 |

35 |

33.5 |

33 |

32 |

30.5 |

29 |

|||

38 |

34 |

33 |

32 |

31 |

30 |

28.5 |

27.5 |

26.5 |

|||

40 |

31 |

29.5 |

28.5 |

27.5 |

25 |

25 |

23.5 |

||||

44 |

25.5 |

24 |

23 |

21.5 |

20.5 |

19.5 |

|||||

48 |

22.5 |

20.5 |

19.5 |

18.5 |

17 |

16 |

|||||

52 |

18 |

16.5 |

15.8 |

14 |

12.7 |

||||||

56 |

14 |

13.2 |

11 |

10 |

|||||||

60 |

11 |

9 |

7.5 |

||||||||

64 |

9 |

7 |

5.7 |

||||||||

68 |

5.5 |

4.5 |

|||||||||

72 |

3.4 |

||||||||||

Wind speed (m/s) |

14.3 |

12.8 |

11.1 |

||||||||

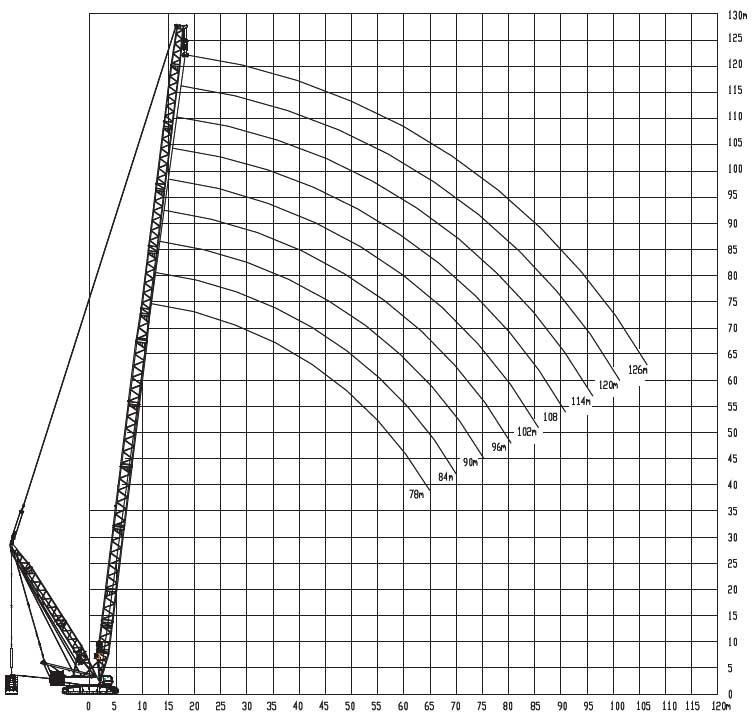

Light-duty main boom lifting height curve

|

|

Light-duty main boom load rating chart(Rear counterweight 140t, ballast 40t, 360 slewing)

|

|

Boom length(m) |

48 |

54 |

60 |

66 |

72 |

78 |

84 |

90 |

96 |

102 |

Falls Radius(m) |

14 |

12 |

11 |

10 |

9 |

8 |

7 |

7 |

6 |

5 |

9 |

180 |

|

|

|

|

|

|

|

|

|

10 |

177 |

142 |

|

|

|

|

|

|

|

|

11 |

169 |

134.0 |

124 |

114 |

|

|

|

|

|

|

12 |

156 |

127.0 |

117 |

109 |

107 |

106 |

|

|

|

|

14 |

133 |

116.0 |

106 |

102 |

102 |

101 |

97 |

84 |

|

|

16 |

115 |

108.0 |

95 |

92.0 |

95 |

96.0 |

92 |

82 |

73 |

63 |

18 |

100 |

94.0 |

85.0 |

83 |

89.0 |

85.0 |

81 |

78.5 |

72.0 |

61.5 |

20 |

87 |

83.0 |

78.0 |

73 |

79.0 |

76.0 |

73.5 |

72.0 |

67 |

60.0 |

22 |

77 |

75.0 |

72 |

64.0 |

71.0 |

68.0 |

65 |

63.3 |

61.5 |

57.0 |

24 |

68 |

67.0 |

65.0 |

60 |

64.0 |

62.0 |

59 |

57.3 |

55.5 |

52.8 |

26 |

61 |

60.0 |

57.0 |

54 |

58.0 |

56.0 |

54 |

52.3 |

50.5 |

48.0 |

28 |

55.0 |

54.0 |

52.5 |

49 |

52.0 |

51.0 |

49.2 |

48.2 |

46 |

44.0 |

30 |

50.0 |

49.0 |

48.5 |

46 |

48.0 |

47.5 |

45.2 |

44.2 |

42 |

40.0 |

32 |

46.0 |

45.0 |

44.5 |

43.0 |

44.0 |

43.0 |

41.5 |

40.6 |

39 |

36.5 |

34 |

42.5 |

42.0 |

41.0 |

40.0 |

40.0 |

39.5 |

38.5 |

37.2 |

35.5 |

33.0 |

36 |

39.5 |

38.7 |

38 |

37 |

37.0 |

36.0 |

35.5 |

34.6 |

33 |

30.0 |

38 |

36.5 |

36.0 |

35.5 |

34.0 |

33.5 |

33.0 |

32.5 |

32 |

30.5 |

27.0 |

40 |

34.0 |

33.6 |

33 |

31.8 |

31.5 |

30.5 |

30 |

29.6 |

28.2 |

24.0 |

44 |

|

29.3 |

28.5 |

27.5 |

27 |

26.2 |

25.5 |

25.2 |

23.5 |

20.0 |

48 |

|

26.0 |

25.0 |

24 |

23.5 |

22.6 |

21.8 |

21.4 |

19.8 |

16.3 |

52 |

|

|

22.0 |

21.2 |

20.3 |

19.6 |

18.5 |

18.1 |

16.7 |

13.1 |

56 |

|

|

|

18.6 |

17.5 |

17.2 |

15.8 |

15.4 |

14.0 |

10.5 |

60 |

|

|

|

|

15.2 |

14.8 |

13.4 |

13.0 |

11.6 |

8.4 |

64 |

|

|

|

|

13.1 |

12.8 |

11.5 |

11.2 |

10 |

6.3 |

68 |

|

|

|

|

|

11.0 |

9.9 |

9.6 |

8.2 |

4.7 |

72 |

|

|

|

|

|

|

8.5 |

8.2 |

6.7 |

3.7 |

76 |

|

|

|

|

|

|

|

6.8 |

5.6 |

3.0 |

80 |

|

|

|

|

|

|

|

|

4.5 |

2.5 |

84 |

|

|

|

|

|

|

|

|

3.5 |

¡ª |

wind speed(m/s) |

12.8 |

11.1 |

||||||||

|

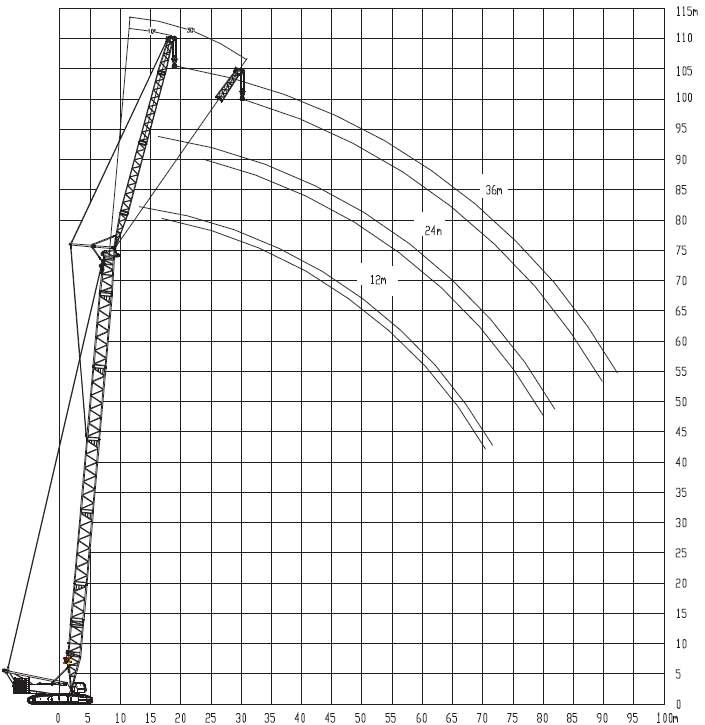

Fixed fly jib lifting height curve |

|

|

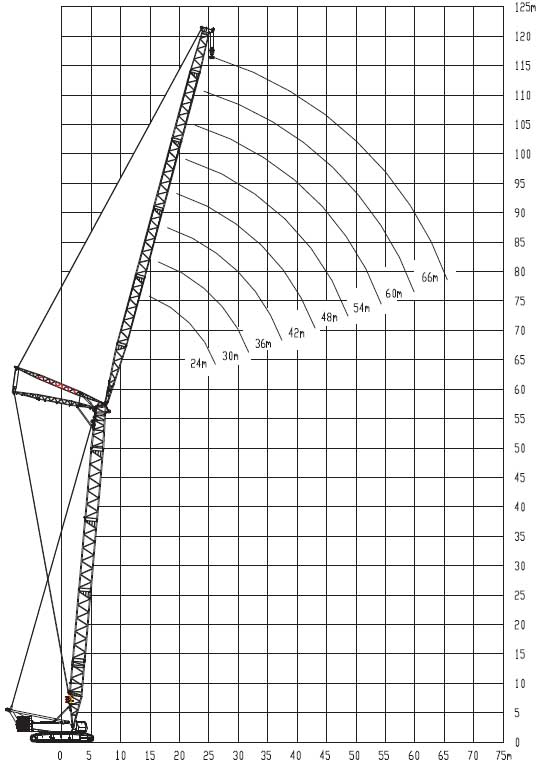

Luffing fly jib lifting height curve |

|

|

Superlifting main boom lifting height curve |

|

|

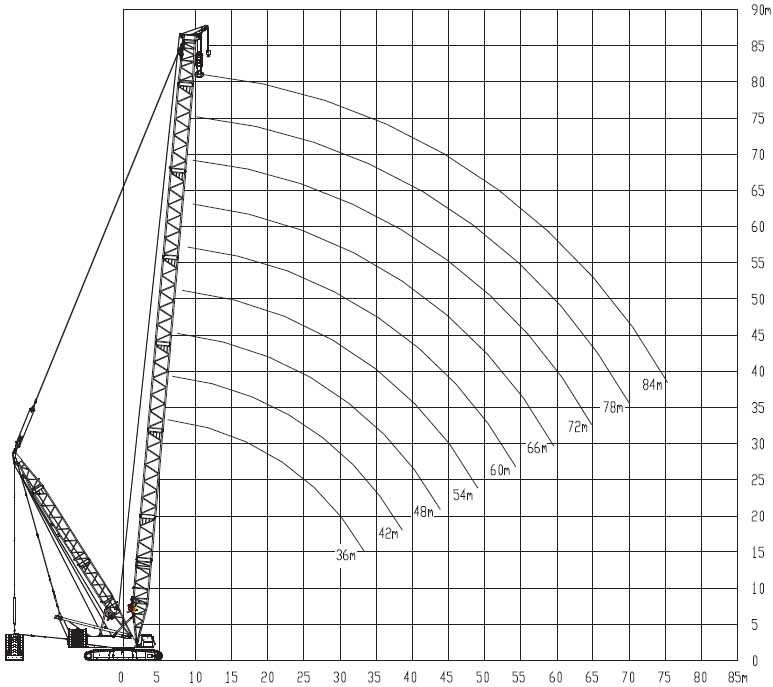

Superllifting light-duty main boom lifting height curve |

|

|

Superlifting luffing fly jib lifting height curv |

|

|

Lifting capacity table of standard boom (Boom length range of 30-72m,fly jib length range of 12-36m,rear counterweight of 40t and 360¡ã all-direction slewing) |

Main boom length(m) |

47

|

|||||||||||||||||||||||

Fly jib Lenght(m) |

12 |

24 |

36 |

12 |

24 |

36 |

12 |

24 |

36 |

12 |

24 |

36 |

||||||||||||

Fly jib mounting angle(¡ã) |

10¡ã |

30¡ã

|

10¡ã |

30¡ã

|

10¡ã |

30¡ã

|

10¡ã |

30¡ã

|

10¡ã |

30¡ã

|

10¡ã |

30¡ã

|

10¡ã |

30¡ã

|

10¡ã |

30¡ã

|

10¡ã |

30¡ã

|

10¡ã |

30¡ã

|

10¡ã |

30¡ã

|

10¡ã |

30¡ã

|

Working radius(m) |

||||||||||||||||||||||||

12.0 |

80 |

80 |

||||||||||||||||||||||

14.0 |

80.0 |

37.8 |

50 |

80.0 |

50 |

80 |

79.5 |

|||||||||||||||||

16.0 |

76.0 |

35.8 |

47.3 |

30 |

79.3 |

36.1 |

47.6 |

80 |

37.5 |

44.9 |

79.5 |

43 |

||||||||||||

18.0 |

72.0 |

33.8 |

44.4 |

28.6 |

74.5 |

34.7 |

45.2 |

27.9 |

80.0 |

36.1 |

43.9 |

79.5 |

36.4 |

42.6 |

||||||||||

20.0 |

67.0 |

32.5 |

41.4 |

27.1 |

70.5 |

33.0 |

42.8 |

27 |

75.0 |

34.9 |

43 |

26.3 |

74.0 |

35.2 |

42 |

26 |

||||||||

22.0 |

62.0 |

30.8 |

38.4 |

19.7 |

25.8 |

64.5 |

31.8 |

40.1 |

19.7 |

26.0 |

64.8 |

33.8 |

42.1 |

25.9 |

64.3 |

34.0 |

41.6 |

25.5 |

||||||

24.0 |

57.0 |

29.7 |

35.4 |

18.8 |

24.3 |

57.0 |

30.5 |

37.4 |

18.9 |

24.5 |

56.8 |

32.7 |

40.8 |

19.7 |

25.5 |

56.0 |

33.0 |

40.5 |

19.7 |

25.1 |

||||

26.0 |

51.5 |

28.6 |

33.5 |

18.0 |

23.3 |

51.8 |

29.4 |

34.9 |

18.1 |

23.4 |

50.3 |

31.7 |

39.0 |

19.1 |

24.9 |

49.3 |

31.9 |

39.2 |

19.1 |

24.8 |

||||

28.0 |

46.5 |

27.4 |

31.2 |

17.2 |

22.2 |

12.1 |

47.3 |

28.1 |

33.2 |

17.5 |

22.5 |

45.2 |

30.7 |

37.3 |

18.4 |

23.5 |

44.3 |

31.0 |

37.6 |

18.6 |

24.0 |

|||

30.0 |

42.6 |

26.4 |

29.2 |

16.5 |

21.2 |

11.6 |

42.7 |

27.1 |

31.1 |

16.9 |

21.5 |

11.9 |

40.5 |

29.7 |

35.5 |

17.9 |

22.8 |

11.6 |

39.5 |

30.0 |

36.1 |

18.0 |

23.3 |

|

34.0 |

36.5 |

24.8 |

25.9 |

15.5 |

19.2 |

10.8 |

35.6 |

25.8 |

27.7 |

15.9 |

19.6 |

11.0 |

32.9 |

27.9 |

32.6 |

17.0 |

21.7 |

11.4 |

31.9 |

28.0 |

32.3 |

17.0 |

21.6 |

11.4 |

38.0 |

30.8 |

23.7 |

23.2 |

14.4 |

17.1 |

10.0 |

29.9 |

24.2 |

24.9 |

14.9 |

17.8 |

10.2 |

27.2 |

26.0 |

28.2 |

16.0 |

20.6 |

10.8 |

26.7 |

25.6 |

27.3 |

16.1 |

20.7 |

10.8 |

42.0 |

26.7 |

22.7 |

21.1 |

13.5 |

15.4 |

9.4 |

25.8 |

23.1 |

22.6 |

14.0 |

16.3 |

9.6 |

22.9 |

23.4 |

23.7 |

15.2 |

19.0 |

10.1 |

21.9 |

22.4 |

23.5 |

15.5 |

19.6 |

10.2 |

46.0 |

23.0 |

21.6 |

19.3 |

12.8 |

14.0 |

8.8 |

22.0 |

21.8 |

20.7 |

13.2 |

14.9 |

9.0 |

19.1 |

20.0 |

20.6 |

14.4 |

17.3 |

9.6 |

18.0 |

19.0 |

20.1 |

14.8 |

18.1 |

9.8 |

50.0 |

20 |

20.5 |

17.8 |

12.1 |

12.8 |

8.2 |

19.0 |

20.6 |

19.1 |

12.6 |

13.6 |

8.4 |

16.0 |

17.0 |

18.0 |

13.7 |

15.9 |

9.1 |

15.0 |

15.5 |

17.0 |

14.1 |

16.7 |

9.2 |

54.0 |

16.6 |

11.6 |

11.7 |

7.8 |

16.3 |

19.3 |

17.2 |

12.0 |

12.5 |

8.0 |

13.2 |

14.1 |

15.2 |

13.1 |

14.7 |

8.6 |

12.2 |

13.1 |

14.2 |

13.5 |

14.4 |

8.8 |

||

58.0 |

15.5 |

11.2 |

10.9 |

7.3 |

15.0 |

11.6 |

11.6 |

7.5 |

11.2 |

11.5 |

12.6 |

12.6 |

13.1 |

8.2 |

9.6 |

10.5 |

11.5 |

12.6 |

12.1 |

8.3 |

||||

62.0 |

10.8 |

10.1 |

7.0 |

13.6 |

11.0 |

10.8 |

7.2 |

9.2 |

8.8 |

10.6 |

11.6 |

11.1 |

7.9 |

7.6 |

8.5 |

9.6 |

11.3 |

10.6 |

8.0 |

|||||

66.0 |

9.5 |

6.8 |

12.2 |

10.6 |

10.1 |

7.0 |

7.4 |

6.4 |

9.3 |

11.0 |

9.7 |

7.4 |

6.4 |

6.2 |

7.7 |

9.7 |

8.7 |

7.6 |

||||||

70.0 |

9.0 |

6.6 |

9.5 |

6.6 |

5.7 |

5.0 |

7.5 |

9.8 |

8.5 |

7.1 |

4.7 |

4.6 |

6.5 |

7.8 |

7.5 |

7.3 |

||||||||

74.0 |

6.4 |

9.0 |

6.4 |

6.4 |

9.0 |

6.8 |

6.9 |

3.5 |

3.4 |

4.8 |

6.0 |

5.8 |

7.0 |

|||||||||||

78.0 |

8.4 |

6.2 |

5.0 |

7.8 |

5.7 |

6.6 |

3.8 |

4.8 |

4.7 |

6.3 |

||||||||||||||

82.0 |

6.3 |

4.7 |

5.9 |

2.7 |

4.1 |

3.7 |

4.8 |

|||||||||||||||||

86.0 |

3.7 |

5.2 |

3.5 |

2.7 |

3.7 |

|||||||||||||||||||

90.0 |

2.8 |

4.6 |

2.7 |

|||||||||||||||||||||

94.0 |

4.1 |

|||||||||||||||||||||||

wind speed (m/s) |

14.3 |

12.8 |

11.1 |

|||||||||||||||||||||

|

Lifting capacity table of standard tower fly jib (Boom length range of 36-54m,tower fly jib length range of 24-66m,rear counterweight of 140t , ballast of 40t and 360¡ã all-direction slewing) |

Main boom length(m) |

36

|

42 |

||||||||||||||||||||||

Fly jib Lenght(m) |

24 |

30 |

36 |

42 |

48 |

54 |

60 |

66 |

||||||||||||||||

Fly jib mounting angle(¡ã) |

85¡ã |

75¡ã

|

65¡ã |

85¡ã |

75¡ã

|

65¡ã |

85¡ã |

75¡ã

|

65¡ã |

85¡ã |

75¡ã

|

65¡ã |

85¡ã |

75¡ã

|

65¡ã |

85¡ã |

75¡ã |

65¡ã |

85¡ã |

75¡ã |

65¡ã |

85¡ã |

75¡ã |

65¡ã |

Working radius(m) |

||||||||||||||||||||||||

14 |

120 |

|||||||||||||||||||||||

16 |

106 |

105 |

||||||||||||||||||||||

18 |

95 |

94 |

91 |

88 |

||||||||||||||||||||

20 |

85 |

84.5 |

82 |

79.5 |

74 |

|||||||||||||||||||

22 |

78 |

71 |

77 |

75 |

72.5 |

67.5 |

64 |

|||||||||||||||||

24 |

71 |

65 |

70.2 |

62 |

68 |

66.5 |

62 |

60 |

56 |

50.5 |

||||||||||||||

26 |

65 |

60 |

64.5 |

57 |

62.5 |

61.5 |

57 |

55.5 |

53.5 |

50 |

||||||||||||||

28 |

55 |

59.5 |

53 |

58 |

51.5 |

56.5 |

53 |

51.5 |

50 |

47.5 |

||||||||||||||

30 |

50 |

55 |

49 |

54 |

47 |

52.5 |

45.5 |

49 |

48 |

46.5 |

45 |

|||||||||||||

32 |

46 |

41 |

51 |

45 |

50.2 |

44 |

49 |

42.5 |

46 |

44.5 |

43 |

42 |

||||||||||||

34 |

38 |

41.5 |

46.5 |

41 |

46 |

39.5 |

43 |

41.5 |

40 |

39 |

||||||||||||||

36 |

35.5 |

38.8 |

34.5 |

43 |

38 |

42.8 |

37.5 |

40.5 |

33 |

39 |

37.5 |

36.5 |

||||||||||||

38 |

33 |

35.8 |

32.5 |

40.5 |

35 |

32 |

40 |

34.5 |

38 |

31 |

37 |

29.5 |

35.5 |

34.5 |

||||||||||

40 |

30.5 |

33 |

29 |

37.5 |

32.5 |

36 |

29 |

35 |

27.5 |

33.5 |

32.5 |

|||||||||||||

44 |

26.5 |

29.5 |

25.5 |

34 |

28.5 |

25.5 |

32.5 |

26 |

31.5 |

24.5 |

30 |

23.5 |

28.5 |

22.5 |

||||||||||

48 |

22.5 |

25.5 |

22.5 |

29 |

23 |

28 |

22 |

26.8 |

20.5 |

25.5 |

19.5 |

|||||||||||||

52 |

19.5 |

21 |

16 |

25 |

19 |

24 |

18.5 |

22.5 |

17.5 |

|||||||||||||||

56 |

17.5 |

19 |

14 |

22.5 |

17 |

13 |

21.5 |

16.5 |

20 |

15 |

||||||||||||||

60 |

12.5 |

15 |

11.4 |

19.3 |

14.5 |

10 |

18 |

13.5 |

8.6 |

|||||||||||||||

64 |

11 |

10 |

12 |

8.8 |

16 |

11.5 |

7.5 |

|||||||||||||||||

68 |

9 |

10.5 |

7.7 |

10 |

6.4 |

|||||||||||||||||||

72 |

6.6 |

8.5 |

5.5 |

|||||||||||||||||||||

76 |

5.8 |

4.8 |

||||||||||||||||||||||

80 |

4.2 |

|||||||||||||||||||||||

wind speed (m/s) |

12.8 |

11.1 |

11.1 |

9 |

||||||||||||||||||||

|

Lifting capacity table of standard tower fly jib (Boom length range of 36-54m,tower fly jib length range of 24-66m,rear counterweight of 140t , ballast of 40t and 360¡ã all-direction slewing) |

Main boom length(m) |

48

|

54 |

||||||||||||||||||||||

Fly jib Lenght(m) |

48 |

54 |

60 |

66 |

48 |

54 |

60 |

66 |

||||||||||||||||

Fly jib mounting angle(¡ã) |

85¡ã |

75¡ã

|

65¡ã |

85¡ã |

75¡ã

|

65¡ã |

85¡ã |

75¡ã

|

65¡ã |

85¡ã |

75¡ã

|

65¡ã |

85¡ã |

75¡ã

|

65¡ã |

85¡ã |

75¡ã |

65¡ã |

85¡ã |

75¡ã |

65¡ã |

85¡ã |

75¡ã |

65¡ã |

Working radius(m) |

||||||||||||||||||||||||

22 |

64.5 |

60.5 |

||||||||||||||||||||||

24 |

59.5 |

57.5 |

52.5 |

57 |

53.5 |

48 |

||||||||||||||||||

26 |

55 |

54 |

51 |

46 |

53 |

51 |

47 |

42 |

||||||||||||||||

28 |

51 |

50 |

48 |

44.5 |

49 |

47.5 |

45 |

41 |

||||||||||||||||

30 |

47.5 |

46.2 |

44.5 |

42.5 |

45.6 |

44.5 |

42.5 |

40 |

||||||||||||||||

32 |

44.5 |

43 |

41.5 |

40 |

42.6 |

41.5 |

40 |

38 |

||||||||||||||||

34 |

42 |

40.5 |

39 |

37.5 |

40 |

39 |

37.5 |

36 |

||||||||||||||||

36 |

39.5 |

38 |

36.5 |

35.5 |

37.6 |

36.5 |

35 |

33.5 |

||||||||||||||||

38 |

37 |

28.5 |

35.5 |

34.5 |

33 |

35.5 |

34.5 |

33 |

31.5 |

|||||||||||||||

40 |

35 |

26.5 |

33.5 |

26 |

32.5 |

31 |

33.5 |

24 |

32.5 |

31 |

29.5 |

|||||||||||||

44 |

31.5 |

23.5 |

30 |

23 |

29 |

21 |

27.5 |

30 |

22 |

29 |

20 |

27.5 |

19 |

26.5 |

||||||||||

48 |

28 |

21.2 |

27 |

21 |

26 |

19 |

24.6 |

18 |

27 |

19 |

26 |

18 |

24.5 |

17 |

23.5 |

16 |

||||||||

52 |

19.2 |

14 |

24 |

18 |

23 |

16.5 |

22 |

15.5 |

17 |

23.2 |

16 |

22 |

14.5 |

20.7 |

13.5 |

|||||||||

56 |

17.2 |

12 |

21.5 |

16 |

10.8 |

20.5 |

14.5 |

19.5 |

13.5 |

15.5 |

9.4 |

20.8 |

14 |

19.5 |

12.8 |

18.2 |

11.5 |

|||||||

60 |

10.7 |

14 |

9.4 |

18.5 |

12.5 |

7.7 |

17.5 |

11.5 |

14.5 |

8 |

12.5 |

6.6 |

17.5 |

11 |

16 |

10 |

||||||||

64 |

9.3 |

12.5 |

8 |

11 |

6.6 |

15.5 |

10 |

5.3 |

7 |

11 |

5.6 |

10 |

4.4 |

14.5 |

8.5 |

|||||||||

68 |

7 |

9.5 |

5.6 |

14 |

8.8 |

4.5 |

6 |

4.8 |

8.5 |

3.7 |

12.8 |

7 |

2.6 |

|||||||||||

72 |

6 |

4.9 |

7.5 |

3.7 |

4.2 |

7 |

3.1 |

6 |

||||||||||||||||

76 |

4.4 |

6.2 |

3 |

2.7 |

5 |

|||||||||||||||||||

80 |

2.5 |

|||||||||||||||||||||||

84 |

||||||||||||||||||||||||

wind speed (m/s) |

11.1 |

9 |

||||||||||||||||||||||

|

Lifting capacity table of superlifting boom (superlifting counterweight range of 0-230t,superlifting mast of 30m,superlifting radius of 15m, rear counterweight of 120t and ballast of 40t) |

Boom length(m) |

|||||||||

working radius(m) |

36 |

42 |

48 |

54 |

60 |

66 |

72 |

78 |

84 |

7 |

400 |

||||||||

8 |

400 |

355 |

350 |

||||||

9 |

385 |

350 |

350 |

328 |

|||||

10 |

372 |

350 |

350 |

318 |

295 |

260 |

|||

11 |

358 |

350 |

348 |

311 |

292 |

257 |

230 |

||

12 |

345 |

341 |

333 |

300 |

288 |

255 |

228 |

193 |

160 |

14 |

316 |

310 |

303 |

280 |

270 |

252 |

226 |

192 |

158 |

16 |

288 |

283 |

277 |

260 |

252 |

238 |

216 |

191 |

157 |

18 |

266 |

261 |

256 |

241 |

234 |

223 |

206.5 |

185 |

155 |

20 |

246 |

241 |

237 |

223 |

217 |

209 |

196 |

177 |

153 |

22 |

227 |

223 |

220 |

208 |

203 |

195 |

184.5 |

170 |

150 |

24 |

206 |

204 |

203 |

195 |

190 |

184 |

174.5 |

163 |

146 |

26 |

193 |

188 |

186 |

182 |

178 |

172.5 |

165 |

155 |

142 |

28 |

177 |

175 |

174 |

171 |

168 |

162.5 |

155.5 |

148 |

136 |

30 |

164 |

164 |

160 |

159 |

158 |

153.5 |

147 |

140 |

129 |

32 |

152 |

152 |

150 |

148 |

146.5 |

144 |

139 |

133 |

123 |

34 |

144 |

141 |

138 |

136.5 |

135 |

132 |

126 |

117 |

|

36 |

135 |

132 |

130 |

129.5 |

128 |

125 |

120 |

112 |

|

38 |

126 |

125 |

123 |

121 |

119 |

117 |

114 |

107 |

|

40 |

119 |

115 |

114 |

11.5 |

110 |

109 |

102 |

||

44 |

102 |

101.5 |

101 |

100 |

97 |

93 |

|||

48 |

94 |

92.5 |

90 |

89.5 |

88 |

82 |

|||

52 |

84 |

82.5 |

81 |

80 |

76 |

||||

56 |

76.5 |

74 |

72 |

69 |

|||||

60 |

67 |

66 |

62 |

||||||

64 |

63 |

62 |

58 |

||||||

68 |

57 |

54 |

|||||||

72 |

50 |

||||||||

wind speed (m/s) |

14.3 |

12.8 |

11.1 |

||||||

|

Lifting capacity table of tower fly jib (superlifting counterweight range of 0-120t,superlifting mast of 30m,superlifting radius of 15m, rear counterweight of 120t and ballast of 40t) |

Boom length (m) |

36 |

|||||||||||||||||||||

working radius(m) |

24 |

30 |

36 |

42 |

48 |

54 |

60 |

66 |

72 |

78 |

84 |

24 |

30 |

36 |

42 |

48 |

54 |

60 |

66 |

72 |

78 |

84 |

14 |

180 |

164 |

||||||||||||||||||||

16 |

172 |

159 |

157 |

145 |

||||||||||||||||||

18 |

161 |

150 |

134 |

116 |

149 |

139 |

122 |

|||||||||||||||

20 |

150 |

143 |

129 |

113 |

142 |

133 |

118 |

104 |

||||||||||||||

22 |

140 |

136 |

124 |

110 |

95 |

134 |

126 |

115 |

101 |

|||||||||||||

24 |

130 |

128 |

118 |

106 |

93 |

127 |

120 |

110 |

99 |

85 |

||||||||||||

26 |

122 |

118 |

112 |

103 |

91 |

76 |

50 |

119 |

114 |

105 |

96 |

84 |

||||||||||

28 |

112 |

108.5 |

106 |

99 |

89 |

75 |

49 |

42 |

112 |

111 |

101 |

93 |

82 |

69 |

46.5 |

38 |

||||||

30 |

98.5 |

97.5 |

95 |

86 |

73 |

48 |

41.5 |

35 |

103 |

96.5 |

89 |

80 |

67 |

46 |

37.5 |

33 |

||||||

32 |

91 |

90 |

89 |

83 |

71.5 |

61 |

48 |

41 |

34.5 |

100 |

93.5 |

86 |

78 |

66 |

57.5 |

45.5 |

37 |

32.5 |

||||

34 |

84 |

83 |

79 |

69 |

59 |

52 |

47 |

40.5 |

34.5 |

95 |

88 |

83 |

76 |

64 |

56 |

45 |

36.5 |

32 |

||||

36 |

78 |

77.5 |

76 |

66.5 |

57 |

51 |

46.5 |

40 |

34 |

81.5 |

81 |

74 |

63 |

55 |

48 |

44.5 |

36.5 |

32 |

||||

38 |

70 |

72.5 |

71 |

64 |

55.5 |

49.5 |

46 |

40 |

33.6 |

72 |

78 |

72 |

61 |

53 |

47 |

43.5 |

36 |

31.5 |

||||

40 |

67 |

66 |

62 |

54 |

48 |

45 |

39.5 |

32 |

67 |

73 |

69.5 |

60 |

51 |

45.5 |

42.5 |

35.5 |

31.5 |

|||||

44 |

60 |

59.5 |

58 |

50 |

45.5 |

43 |

37.5 |

26.2 |

63 |

64 |

56 |

48.5 |

44 |

41 |

34.5 |

26.4 |

||||||

48 |

52.5 |

52 |

46 |

43 |

41 |

34.5 |

23.9 |

57 |

53 |

46 |

41.5 |

39.5 |

33.5 |

24.2 |

||||||||

52 |

47 |

42 |

41 |

40 |

31.5 |

22 |

51 |

44 |

40 |

38.5 |

31.8 |

22.3 |

||||||||||

56 |

42.5 |

39 |

39 |

36.5 |

26.8 |

20.2 |

45.5 |

40 |

38 |

37.5 |

27 |

20.5 |

||||||||||

60 |

37 |

36.5 |

33 |

25.1 |

18.8 |

37.5 |

35.5 |

35 |

25.3 |

18.9 |

||||||||||||

64 |

34 |

30.5 |

23.4 |

17.4 |

34 |

32 |

23.8 |

17.5 |

||||||||||||||

68 |

27.4 |

21.3 |

15.7 |

32.5 |

27.7 |

24.2 |

15.7 |

|||||||||||||||

72 |

25 |

19.2 |

13.9 |

25.6 |

21.6 |

14.1 |

||||||||||||||||

76 |

17.5 |

12.4 |

19.5 |

12.6 |

||||||||||||||||||

80 |

11.1 |

11.2 |

||||||||||||||||||||

84 |

10.1 |

10.2 |

||||||||||||||||||||

wind speed (m/s) |

9.0 |

|||||||||||||||||||||

|

Lifting capacity table of superlifting tower fly jib (superlifting counterweight range of 0-120t,superlifting mast of 30m,superlifting radius of 15m, superlifting radius of 15m,rear counterweight of 120t and ballast of 40t) |

Boom length (m) |

54 |

60 |

||||||||||||||||||||

working radius(m) |

24 |

30 |

36 |

42 |

48 |

54 |

60 |

66 |

72 |

78 |

84 |

24 |

30 |

36 |

42 |

48 |

54 |

60 |

66 |

72 |

78 |

84 |

16 |

139 |

112 |

123 |

|||||||||||||||||||

18 |

130 |

108 |

116 |

97 |

||||||||||||||||||

20 |

121 |

103 |

110 |

93.5 |

77 |

|||||||||||||||||

22 |

114 |

98 |

93.5 |

103 |

89.5 |

75 |

||||||||||||||||

24 |

106 |

95 |

90 |

80 |

54.5 |

99 |

86 |

81 |

73 |

|||||||||||||

26 |

99 |

92 |

86.5 |

77 |

53.5 |

46 |

94 |

83.5 |

78 |

71 |

49 |

|||||||||||

28 |

94 |

90 |

83.5 |

75 |

68 |

52.5 |

45 |

40 |

90 |

81.5 |

75 |

68 |

48 |

42 |

37 |

|||||||

30 |

87 |

80 |

72 |

66 |

59.5 |

51.5 |

44.5 |

39 |

33.5 |

86 |

80 |

72 |

65 |

60 |

47 |

41 |

36 |

31.3 |

||||

32 |

84 |

78 |

70 |

64.5 |

58 |

50.5 |

43.5 |

38.5 |

33 |

28.5 |

79 |

70 |

63 |

58 |

53 |

46 |

40 |

35.5 |

30.8 |

26.7 |

||

34 |

77 |

68 |

62.5 |

57 |

49.5 |

43 |

38 |

33 |

28 |

77 |

69 |

62 |

57 |

52 |

45 |

39.5 |

35 |

30.3 |

26.5 |

|||

36 |

75.5 |

66 |

60.5 |

55 |

48 |

42 |

37.5 |

32.5 |

27.8 |

45 |

68 |

60 |

55 |

50 |

44 |

39 |

34.5 |

29.8 |

26 |

|||

38 |

73 |

65 |

59.5 |

54 |

46.5 |

41 |

37 |

32 |

27.5 |

67 |

59 |

54 |

49 |

42.5 |

37.5 |

33.5 |

29.5 |

25.8 |

||||

40 |

71 |

64 |

57.5 |

52.5 |

45 |

40 |

36 |

31.5 |

27.2 |

65 |

57.5 |

52.5 |

47.5 |

41.5 |

36.5 |

33 |

29 |

25.5 |

||||

44 |

60 |

55.5 |

50 |

42.5 |

37.5 |

34.5 |

31 |

26.6 |

54.5 |

50.5 |

45.5 |

39.5 |

34.5 |

31.5 |

27.8 |

25.2 |

||||||

48 |

52.5 |

48 |

41 |

35.5 |

33 |

29.5 |

24.8 |

48 |

43.5 |

37.5 |

32.5 |

30 |

26.5 |

23.8 |

||||||||

52 |

48 |

45 |

39 |

34 |

31 |

28.5 |

22.7 |

46 |

41.5 |

35.5 |

31 |

28.5 |

25.5 |

22.8 |

||||||||

56 |

42 |

36.5 |

31.5 |

28.5 |

27 |

20.9 |

40 |

33 |

29.3 |

26.8 |

24.5 |

21.1 |

||||||||||

60 |

34.5 |

29.5 |

26.5 |

25 |

19.3 |

31 |

27.2 |

25 |

23 |

19.5 |

||||||||||||

64 |

27.5 |

24.5 |

23.3 |

17.9 |

28 |

25.2 |

23.3 |

21.5 |

18.1 |

|||||||||||||

68 |

25.5 |

23 |

21.5 |

16.5 |

23 |

21.7 |

20 |

16.8 |

||||||||||||||

72 |

21.5 |

20 |

14.6 |

20.2 |

18.5 |

14.8 |

||||||||||||||||

76 |

18.2 |

12.9 |

17.2 |

13.1 |

||||||||||||||||||

80 |

16.5 |

11.6 |

15.5 |

11.8 |

||||||||||||||||||

84 |

10.4 |

10.6 |

||||||||||||||||||||

wind speed (m/s) |

9.0 |

|||||||||||||||||||||

|

Lifting capacity table of superlifting tower fly jib (superlifting counterweight range of 0-120t,superlifting mast of 30m,superlifting radius of 15m, superlifting radius of 15m,rear counterweight of 120t and ballast of 40t) |

Boom length (m) |

72 |

84 |

||||||||||||||||||

working radius(m) |

24 |

30 |

36 |

42 |

48 |

54 |

60 |

66 |

72 |

78 |

84 |

36 |

42 |

48 |

54 |

60 |

66 |

72 |

78 |

84 |

18 |

90 |

80.5 |

||||||||||||||||||

20 |

85 |

78 |

70 |

|||||||||||||||||

22 |

81 |

75 |

68 |

61 |

55 |

48.5 |

||||||||||||||

24 |

78 |

72.5 |

66 |

59 |

53 |

47.5 |

53 |

47.5 |

42 |

|||||||||||

26 |

75 |

70 |

63.5 |

57.5 |

52 |

46.5 |

40 |

51 |

46 |

41 |

37 |

|||||||||

28 |

73 |

68.5 |

61.5 |

56 |

50.5 |

45.5 |

39.5 |

34 |

49 |

44.5 |

40 |

36 |

32.5 |

|||||||

30 |

71.5 |

67 |

59.5 |

54 |

49.5 |

44.5 |

39 |

33.5 |

30 |

47 |

43 |

38.5 |

35 |

31.5 |

27.8 |

24 |

||||

32 |

66 |

58 |

52 |

48 |

43.5 |

38 |

33 |

29.5 |

25.6 |

22 |

45.5 |

41.5 |

37.5 |

34 |

30.7 |

27.2 |

23.5 |

21 |

||

34 |

64.5 |

57 |

51 |

46.5 |

42 |

37 |

32 |

28.8 |

25 |

21.6 |

44.5 |

40.5 |

36.5 |

33 |

30 |

26.5 |

23.2 |

20.5 |

17.3 |

|

36 |

62 |

55.5 |

49.5 |

45 |

41 |

36 |

31.5 |

28.3 |

24.7 |

21.2 |

44 |

39.5 |

35.5 |

32 |

29 |

25.8 |

22.5 |

20.2 |

16.9 |

|

38 |

54.5 |

48 |

44 |

40 |

35.5 |

31 |

27.7 |

24.2 |

20.8 |

43 |

38.5 |

35 |

31 |

28.2 |

25.2 |

22.2 |

19.7 |

16.1 |

||

40 |

53.5 |

47 |

42.8 |

39 |

34.5 |

30 |

27 |

23.8 |

20.5 |

42 |

37.5 |

34 |

30 |

27.4 |

24.5 |

21.5 |

19.2 |

15.4 |

||

44 |

45.5 |

41.5 |

37 |

33 |

28.5 |

25.8 |

22.7 |

19.7 |

36 |

32.5 |

28.5 |

25.8 |

23.2 |

20.6 |

18.2 |

13.9 |

||||

48 |

42.5 |

40 |

35.5 |

31.5 |

27 |

24.4 |

21.6 |

19 |

34.5 |

31 |

27 |

24.6 |

22 |

19.5 |

17.2 |

12.9 |

||||

52 |

38.5 |

34.5 |

30 |

25.5 |

23 |

20.5 |

18 |

30 |

26 |

23.7 |

21 |

18.5 |

16.3 |

12.3 |

||||||

56 |

33.5 |

28.5 |

24.3 |

21.8 |

19.4 |

17 |

25.5 |

22.8 |

19.8 |

17.5 |

15.1 |

11.7 |

||||||||

60 |

26 |

22.8 |

20.7 |

18.3 |

16 |

24.5 |

22 |

19 |

16.4 |

14.1 |

11.3 |

|||||||||

64 |

24 |

21.5 |

19.5 |

17.4 |

15 |

21.2 |

18.3 |

15.8 |

13.5 |

10.8 |

||||||||||

68 |

20 |

18.2 |

16.3 |

14.3 |

17.8 |

15.3 |

13.3 |

10.5 |

||||||||||||

72 |

16.9 |

15.2 |

13.3 |

14.8 |

13 |

10.3 |

||||||||||||||

76 |

14.5 |

14.2 |

12.2 |

14.2 |

12.5 |

10.1 |

||||||||||||||

80 |

13.2 |

11 |

11.7 |

9.9 |

||||||||||||||||

84 |

10 |

9.2 |

||||||||||||||||||

88 |

8.2 |

|||||||||||||||||||

wind speed (m/s) |

9.0 |

|||||||||||||||||||

| Note: All specifications on our web-site are subject to technical modifications without notice. |

| Download Infomation |